In the modern world, gears have witnessed revolutionary usage in every aspect of our lives. To ease our worries and reduce our efforts drastically, various experts have painstakingly come up with this simple yet extremely useful technological application in the machinery. Read on to know more about the most reliable !

Thank you for reading this post, don't forget to subscribe!What’s a hob and what do you use it for?

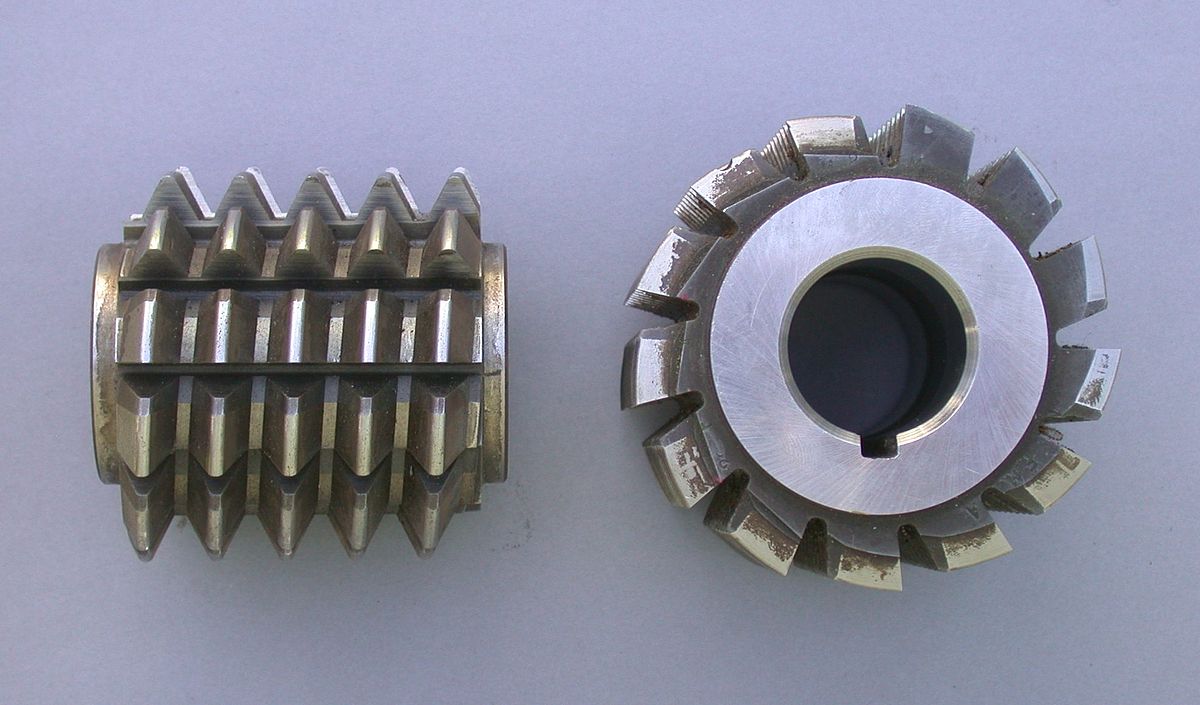

Hobs are used to dent into or cut through materials using mechanical gears that help you get a better grip over the process. It uses a bunch of mechanical gears connected through advanced technology that maximizes output and efficiency. Hobs have a cylindrical shape accentuated by helical cutting teeth, featuring grooves that run throughout the length of the hob. Based on your requirements and usage, you may acquire general-purpose hobs or demand a custom-built one. However, make sure that you don’t underestimate their difference. To obtain a perfect finish and edge to your project upon completion, you need to differentiate between the different hobs available and determine which suits your intentions the best. Good manufacturers and experienced dealers will make it a point to enhance every hob singularly to emphasize their importance – this will help you decide on what to purchase!

Hobs are very popular thanks to their competence in getting the job done faster; they are comparatively inexpensive as well. The mechanical process of manufacturing gears uses hobs as well. So starting from cycloid gears, through ratchets and sprockets, to worm gears – you can get it all fortunately because of the excellent hobs making your job a lot simpler!

Necessary features to look for to determine a good purchase

To accomplish an efficient production of highly utilizable and strong hobs, you need to make sure that the manufacturing process made use of top-notch technology to result in the best metallic alloy for your gear products. Nowadays, the method of cryogenic hardening has become tremendously popular and is being extensively used all around for effective manufacturing procedures.

The manufacturers and experts understand the requirement of mass production of gear hobs. Gear hob cutters need to be regularly replaced to ensure consistently good efficiency and reliable outcome from them. Deep cryogenic treatment reduces the time taken to repair the hobs and restore their edges efficiently without increasing any expenditure anywhere. This has highly reduced the number of times you will be forced to replace the hob saw teeth over a certain interval of time. For proficient working, the hobs need to continue to stay sharp and free from excessive wear and tear. So, make sure you take good precautions against friction!

Get the best gear hobs today!

You can browse through various types and kinds of gear online. Now that you know all about their usage and capabilities, you won’t have any problem choosing the best products! Find trustworthy manufacturers and purchase the best gear products today! We prioritize your comfort and satisfaction the most!