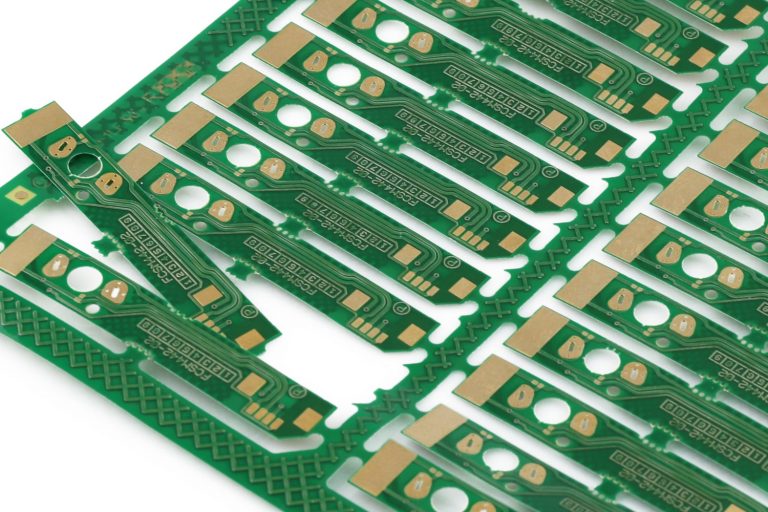

During panelization of PCB, it is essential to follow certain procedures that would ensure that the board will be robust. This includes the use of Breakaway rails and V-groove breakouts.

Thank you for reading this post, don't forget to subscribe!AAAA combination panelization

ABAA combination panelization of PCB is a good way to improve the efficiency of PCB manufacturing. The process also helps in reducing the inventory of semi-finished products. This can be a huge help for manufacturers looking to reduce costs.

A PCB is made up of different components, all of which have to be arranged in a certain order. This is a complex task that may cause some confusion. It’s important to determine the best PCB panelization method in order to ensure a successful breakout. Using the wrong panelization method may lead to a poor-quality board.

For small PCB designs, panelization is the best manufacturing method. Panelization methods are designed to optimize space and minimize the cost of the manufacturing process. It’s also a good idea to ask the fabricator for a standard panel size. This will help the manufacturer manufacture multiple PCBs in a short amount of time.

V-groove breakout method

Choosing a breakout strategy can be influenced by the type of components used, their placement and even the design of your array. The breakout method can be a crucial factor in your project’s success.

One common breakout technique is the V-groove. This is a v-shaped groove that separates individual PCBs. In this case, the copper traces are very close to the board edge. This creates a potential problem for your project.

If you’re planning on using the V-groove breakout method for panelization, be sure to place your components far from the groove. This may be especially important for components that hang over the edge of the board.

During the break-out process, the PCB can be stressed. This stress transfers through the board surface and through the component solder joints. This can cause stress fractures and breakage of the solder joints.

Three-hole pattern breakouts

Whether you’re a designer or a PCB manufacturer, there are many things to consider when panelizing a circuit board. From material to design, your choice of breakout method can make or break your assembly process. In fact, some materials can actually splinter during the breakout process, leaving your PCB vulnerable. Fortunately, there are ways to keep your boards safe.

There are two primary methods of panelizing a PCB. One involves a groove, and the other uses perforated tabs. The v-groove method is a good choice for square or long straight boards, while the tab routing method is best for odd-shaped boards.

The V-groove method is a bit more restrictive than the tab routing method, but it has several benefits. First, it uses less space than the tab routing method, allowing the board to be processed faster.

Breakaway rail

During assembly of a PCB, it is vital to create proper clearances. For example, components that hang over the edge of the board will need to be placed at least three mm away from the mouse bites.

Another way to do this is by routing the boards. Routed boards are made with perforations in the PCB. They allow the boards to be easily separated after manufacturing. They are used in combination with other techniques to give the array strength.

One method of separating a PCB is using a breakaway rail. This is also called an edge rail. The rail is removed during depanelization and can help prevent damage to the PCB at the edges.

Another method of separating a PCB is by scoring. This technique is commonly used to separate rectangular or irregular shapes. The PCB is scored across the board outline.

PCB design needs to be more robust

Using a PCB panelization technique can make the manufacturing process easier and more cost-effective. However, there are some things to consider when choosing a technique.

The size of the board itself can also impact your panelization choice. For example, a thicker board will require more material between boards. This will ensure that the panel is sturdy and capable of enduring the assembly process.

Another consideration is the type of copper used. For instance, FR-4 is the most common type of PCB material, and is suited to most applications. Its properties include tolerance to different temperatures, which can be very helpful when designing a PCB.

The number of breakout tabs can affect how easily a panel is depanelized. Having too few tabs can complicate the process. The number of tabs can also depend on the size of the board.